Application in all kinds of vehicles, boats, machines, and installations with a drive power of 140

kW under hard application conditions, especially as 4Q-servo-drive for

- highly dynamic acceleration and braking cycles

- a wide control range

- a high efficiency

- small motor dimensions

- a uniform, accurate and smooth running

- for the speed or torque control or combined speed/torque control incorporated within or

independent of position control loops. For drives with constant speed as in conveyors, spindle

drives, pumps, transversal or longitudinal pitch drives, synchronous multiple motor drives.

Particularly suitable for:

Battery-driven vehicles such as electric vehicles and boats, forklifts, transportation systems as well

as battery-supplied machines and installations such as assembly machines, metal working

machines, food processing machines, robots and handling systems, conveyors, stone working

machines, and for many other battery-supplied applications.

Build:

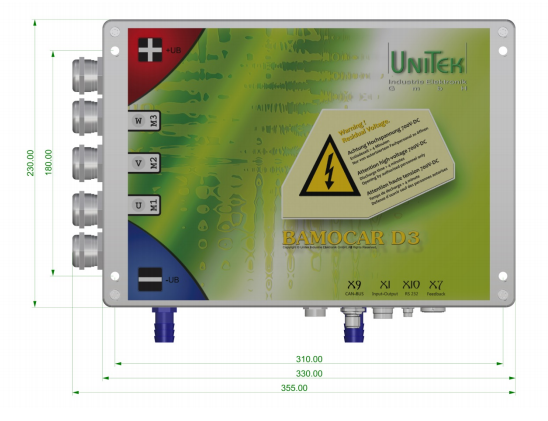

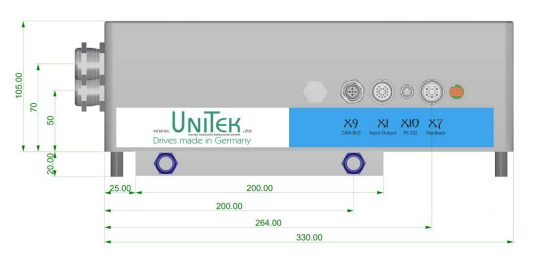

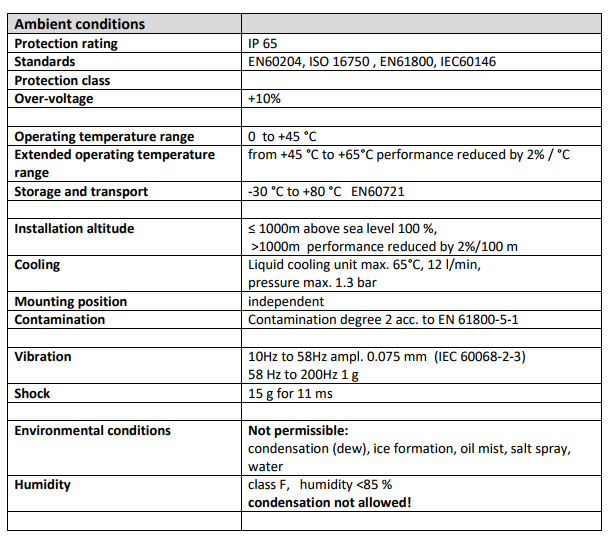

-Robust unit for switch cabinet mounting according to the VDE, DIN and EC regulations,

protection rating IP65

-for rough ambient conditions and high dynamic overloads

-maintenance-free

-power connections protected against accidental contact with exposed parts

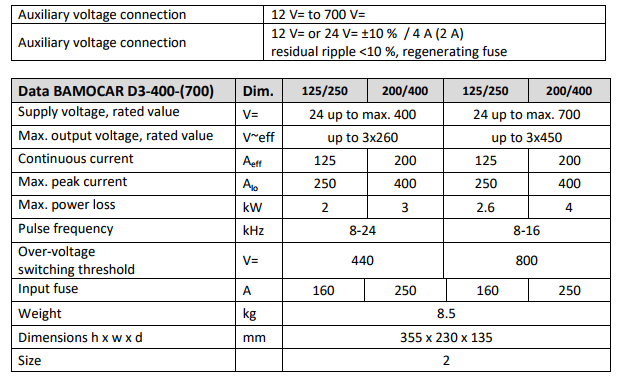

-power electronics for (S1 operation) 125 A, 200 A

-power input range nom. 12 to 700 V=

-liquid cooling (special version air cooling)

-standard digital control electronics

-Independent 12/24 V chopper power supply unit for the auxilary voltages

Galvanic isolation between:

- power connection, motor connection, and all other control connections

- auxiliary connection and all other voltages

- housing and heat sink

- the distances of air gaps and leakage paths adhere to the EU standards

- no internal isolation watchdog, Y2 capacitors to the housing

Components:

- Completely isolated IGBT power semi-conductors, comfortably over-dimensioned

- Only components customary in trade and industrially standardised are used

- SMD equipment

Characteristics:

Battery connection 12 V= to 700 V= (dc mains, take restrictions into account)

- Independent auxiliary voltage connection 24 V= or 12 V=

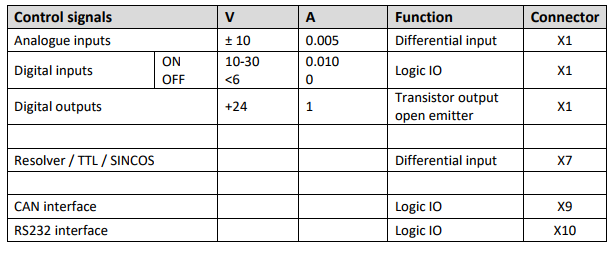

- Digital interfaces RS232, CAN BUS (further option)

- 2 analogue inputs, programmable differential inputs

- Digital inputs/outputs, programmable, optically de-coupled

- Linear command value ramp, non-linear (s-function)

- Logic for enable and the output stage switch, emergency stop function, safety

- BTB ready for operation, solid state relay contact

- Position, speed and torque control Feedback encoder systems: resolver, incremental encoder, SINCOS 1 Vss, rotor position + bl tacho

-Static and dynamic current limiting

- Uniform, completely digital control unit

- Processor-independent hardware switch-off in case of over-voltage, under-voltage, shortcircuits,

circuits to earth, and over-temperature at the amplifier or motor

-Intrinsically safe and short-circuit proof power section (EN50178)

Technical data For three-phase current motors.

|